Tikkurila – over 160 years of decoration and protection

PPG Tikkurila was established in Finland on August 14, 1862 on the bank of the River Keravanjoki, about ten miles to the north of the capital Helsinki.

At first, linseeds were compressed into animal feed cakes, and untreated linseed oil was used for surface treatment. Varnish cooking began in 1867, and the manufacture of paints and lacquers in industrial scale in 1919. Extensive marketing and customer training activities, which were started in the 1920s, still continue today. In the 1960s Tikkurila expanded its operations to cover tinting technology as well, but in 2000 the company returned to its roots – the development, manufacture and marketing of paint.

Linseeds and hydropower 1862–1882

The tale of Tikkurila Oy as we know it today began in the village of Dickursby (Tikkurila) in the Helsinge parish, near the city of Helsinki. The first water mill on the Tikkurilankoski rapids of the River Keravanjoki was built in 1757, and an oil press was established alongside the water mill in 1862. Dickursby Oljeslageri, owned by Lieutenant Colonel Anders Lorentz Munsterhjelm, utilized flax and hemp seeds in its production. Linseed oil was itself a finishing material which could be boiled to produce varnish, a binder for paint.

The original location of the oil press remains ideal in terms of logistics. The original setting has alos allowed the company to expand in its chosen directions. Though the plant no longer stands by the river, the office windows still open out onto a view of the rapids.

Business was international even back in the 1860s, when Finland was a grand duchy of Russia. The borders to the vast Russian empire were open to suppliers of both raw materials and finished products, and close links were also retained with Sweden, Finland's former mother country.

Lieutenant Colonel Anders Lorentz Munsterhjelm, owner of Tikkurila Manor, was given permission to establish "an oil press based on the utilization of flax and hemp seeds" on August 14, 1862.

Dickursby Oljeslageri passed through many hands until it was taken over in 1885 by Schildt & Hallberg. This undertaking, established in 1877 for the purposes of "trading, mainly comprising agency operations as well as commission trade and exports," had over the years turned to wholesale. The firm traded in flour and grain, dairy equipment and agricultural machinery, concentrated fodder, fertilizers and seed grain.

Schildt & Hallberg took an interest in the oil press partly because the company already had a market for the oilcakes made into animal fodder from the exhausted linseeds. In return, Schildt & Hallberg purchased the flax seeds grown by their customers.

The exports of Schildt & Hallberg also included the seeds of Finnish conifers. In 1886, a seed-extraction plant with a daily capacity of 24 barrels of pine cones was built in Tikkurila. Conifer seeds from Tikkurila were held in such renown abroad that they were awarded the silver medal at the Paris World Expo in 1889. Much of the forests in northern Germany probably grew from these seeds, which were exported to France, Belgium and Britain as well.

The old linseed oil boiling plant was replaced in 1889. The first hydraulic oil presses were obtained in 1897, when new boilers were also added to the factory. As domestic linseed supply was not fully capable of meeting demand, raw material was occasionally shipped in from as far afield as Argentina. Production increased to the point where the Tikkurila oil press started to become a significant player in the varnish market. At the time the market in Finland, as well as elsewhere, was virtually dominated by the Russian Newsky varnish.

The oil press was expanded and modernized in the early 1900s by obtaining new machinery and equipment to increase the oil output of flax seeds. A fire that practically destroyed the varnish plant in 1912 caused only a brief interruption in production.

The outbreak of World War I marked the beginning of a boom for Tikkurila. As imports of Russian varnish were discontinued, demand for Tikkurila varnish grew to such an extent that production had to be shared among the country's ironmongers according to quotas. However, the aftermath of 1917 also brought an end to the imports of raw material – flax seeds – from Russia, and the oil press was out of operation for the whole of the following year.

Around this time, cooperative societies had strengthened to a point where "old-fashioned" wholesalers – such as Hjalmar Schildt and Mauritz Hallberg – closed down or switched trades. In 1917 the trading firm became a limited company Ab Schildt & Hallberg Oy with its focus on industry.

Construction had taken off during the war and merely intensified with peace, encouraging investment in the paint industry. The war had also taught a valuable lesson about the importance of national self-sufficiency in key commodities, including paints and lacquers. This field was perfectly suited to a company that already owned an oil press and varnish factory, and had capital and good domestic business contacts to boot.

The early days were nevertheless far from rosy. Imports of foreign products started as soon as a newly independent Finland opened diplomatic relations with foreign nations. The toughest competition came from companies in the Netherlands, Germany, Great Britain and Sweden.

The paint and lacquer factory that was established in Tikkurila in 1919 was not the only Finnish business in the field; Suomen Väri- ja Vernissatehdas Oy had a small plant in Helsinki, in addition to which there were the Frisenborg factories, the Björkell technical factory, Ullrich, Anderzen & Co. and the Höijer spirit lacquer plant. All these domestic undertakings were fairly marginal, however, as foreign products dominated the market.

Probably the greatest hindrance to success was the relative obscurity of Tikkurila varnish, paints and lacquers. Their equal or even superior quality to competing products was yet to become a matter of public knowledge. In order to attain closer contacts with retailers and professional painters in particular, an intense image campaign was started at the initiative of procurator Albin Sandström.

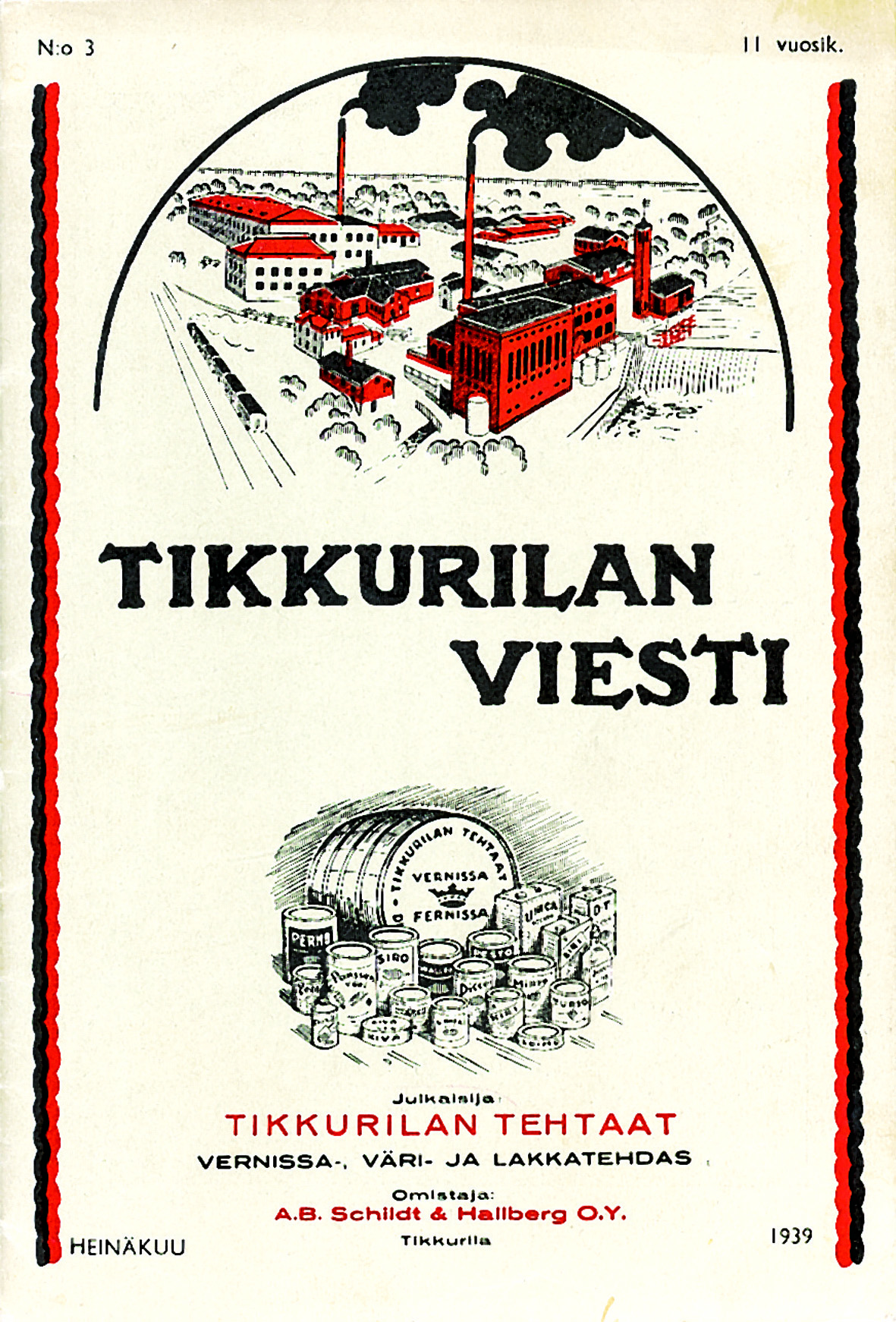

A customer magazine "Tikkurilan Viesti", in Swedish "Dickursby Meddelanden", was founded in 1929 in oder to win customer confidence through "enlightenment". The magazine has been published regularly ever since, except for six-year break during World War II.

The company fared relatively well in the economic depression of the 1920s, thanks to the paint and lacquer factory. The year 1929 saw the beginning of a busy period of new construction at Tikkurila that lasted through the following decade.

Tikkurila first started training customers in the late 1920s.

The 1930s were a time of technological advances at Tikkurila and production volumes rose significantly. Chemical research and synthetic raw materials changed both the paint-making process and the paints themselves. Trailing demand for varnish and raw material shortages due to World War II only exacerbated a difficult situation.

Tikkurila's production facilities suffered little damage during the war, though air raid warnings often interrupted operations. More than a few Tikkurila employees gave their lives fighting for their country.

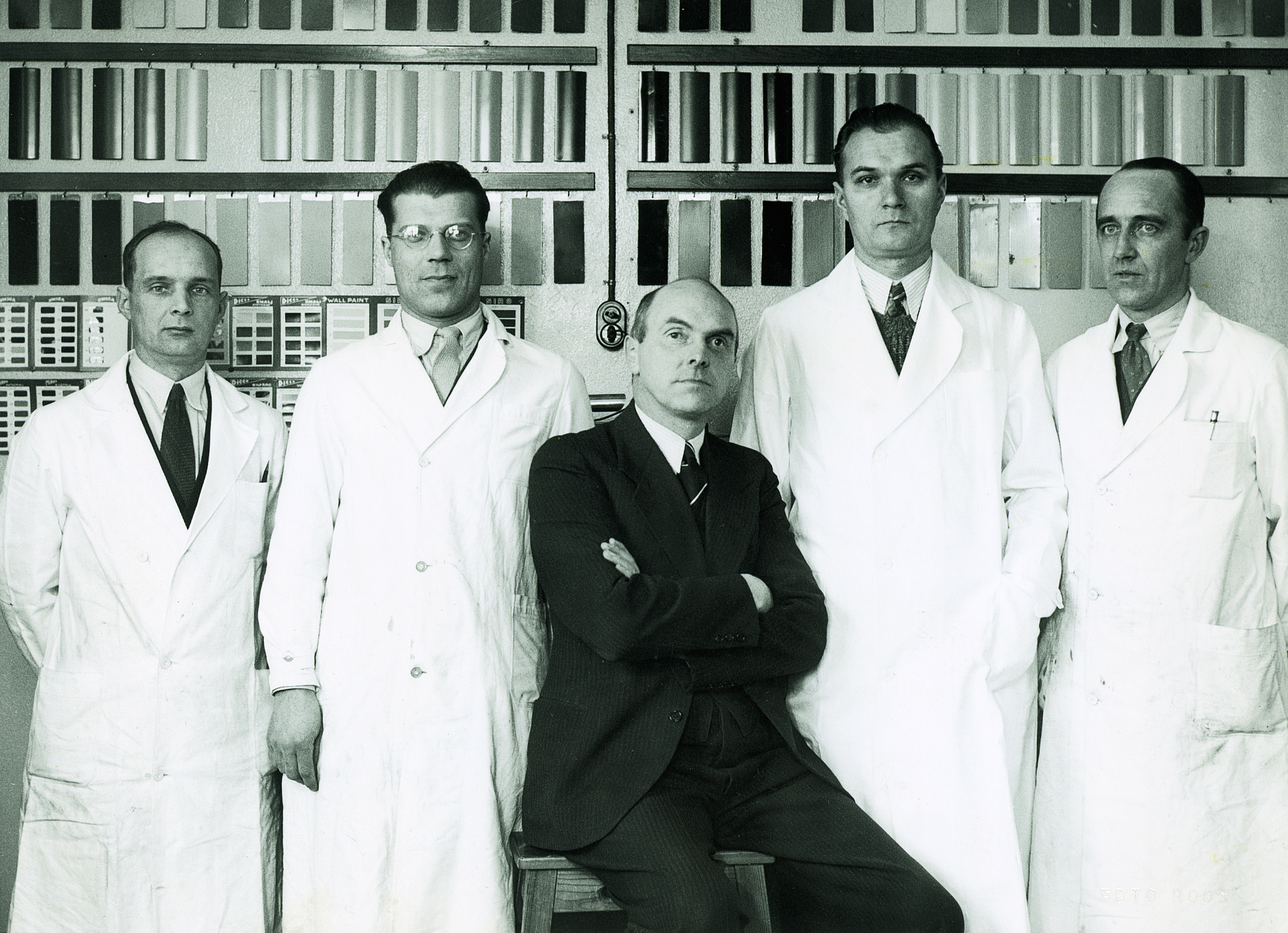

Production was wholly dependent on domestic raw materials, putting the ingenuity of company chemists to the test. Fortunately, the company had amassed a wealth of valuable knowledge. Before coming to Tikkurila in 1923, technical director Ragnar Holmström had studied in Germany and worked for chemical companies in both Russia and the United States. It is no exaggeration to say that this was the time when the foundations for Tikkurila's current, intense product development programme were laid.

In 1933, the company set up its own fire brigade, partly due to the influence of the Fire Act that entered into force in Finland the same year. Until 1960, the Tikkurila factory fire brigade was also under contract to serve the then Helsinge rural district, today known as the city of Vantaa.

Post-war Finland witnessed an abundance of painting and construction. Tikkurila's own employees were not immune from the acute shortage of housing, to which the company responded by building staff housing. Low-interest loans granted by the company encouraged employees to become homeowners.

The company set to work on improving other social benefits for personnel as well. The company had established a financial services office for personnel in the early 1920s. In wartime, the company also looked after the families of men called up for military service, and especially families of the fallen. The staff canteen, opened in the 1930s, started serving free meals – of particular significance during the wartime food shortages. A company nurse, in cooperation with the municipal doctor, provided health care for employees and their families.

Increased attention was paid to the prevention of fires and accidents. Extensive work was done to improve the safety of personnel and premises.

As of 1946, a statutory production committee saw to cooperation between plant management and personnel. The company of its own accord launched an initiatives programme in 1953 to collect suggestions on improving production and reducing the number of industrial accidents.

In 1950 the company started its own staff magazine "to build on the feeling of solidarity." Johan Rosenberg, who had joined Tikkurila the previous year in the capacity of social manager, had journalistic experience and was thus appointed editor-in-chief of the Sävyseppo – Färgstänk magazine. He held the job for 40 years, serving also as factory fire brigade chief and communications manager.

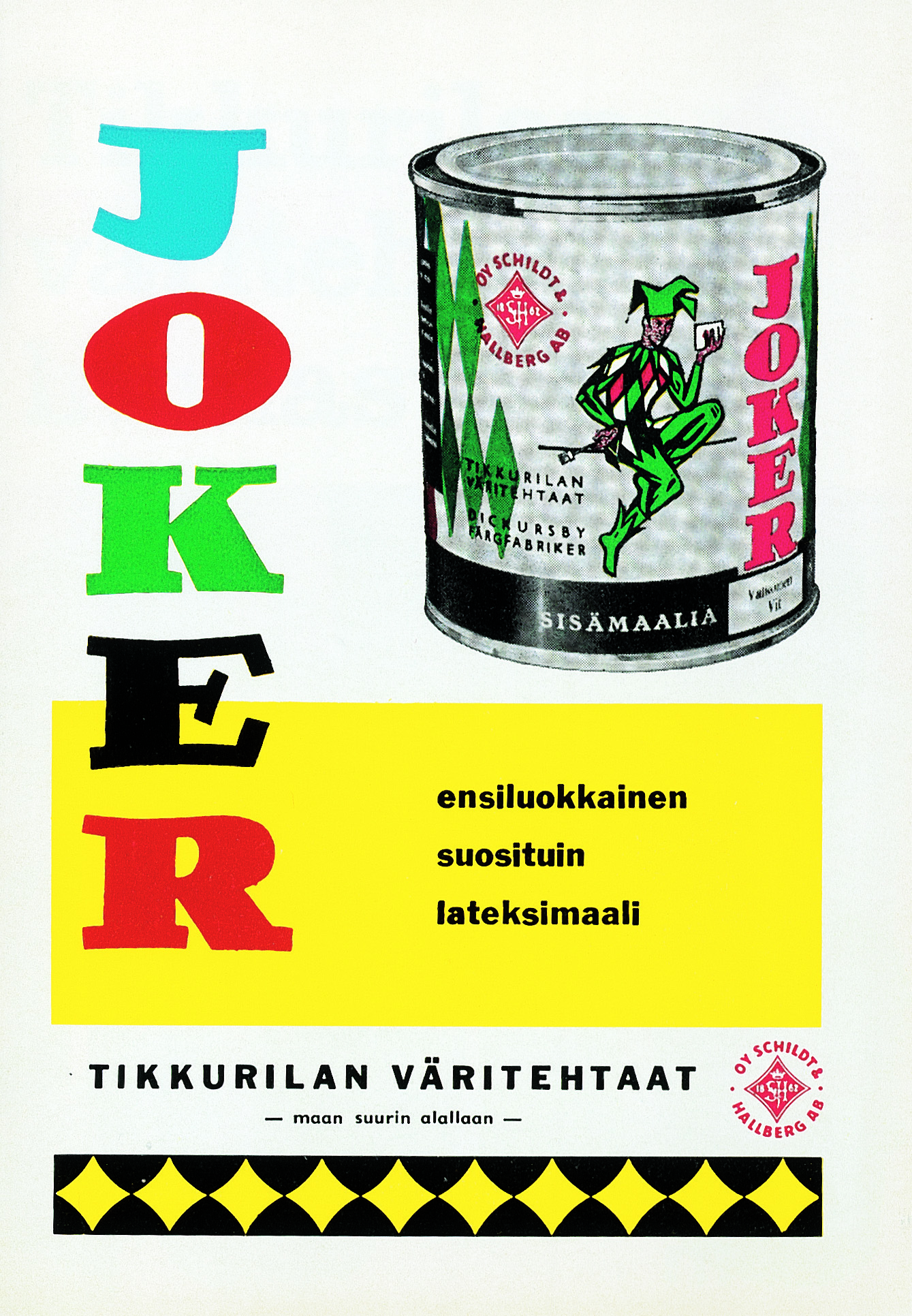

The extensive U.S. production of synthetic rubber started experiencing marketing difficulties after World War II. Once again the paint industry came to the rescue, as it had done in respect of cellulose nitrate (nitrocellulose) after World War I. The invention of polystyrene-butadiene latex marked the beginning of the triumph of latex products as interior and outdoor paints. Joker, Tikkurila's first water-borne paint for interior use, was launched in 1953.

A number of factors contributed to the popularity of latex paints. They allowed the use of paint rollers, which significantly speeded up the work. Latex paint had a milder odor than earlier paints, but at this point the issue was not yet directly linked with occupational health or environmental protection. In the 1960s latex paints were the most widely used interior paints.

Marketing was given a boost in 1958 with the establishment of a coloring service entrusted with monitoring and developing color cards and producing color schemes. This type of service was a novelty in Finland, perhaps in all of Europe. The coloring of many a Finnish home from the 1950s to the 1970s was the handiwork of artist Yki Nummi, director of the service. The service was also considered socially significant, as the color schemes for many public buildings, production facility complexes and even entire neighborhoods were determined on the basis of its advice. The service was free of charge and available to everyone.

The oil press had been experiencing difficulties since the war because of a shortage of raw materials. Imports remained sluggish into the 1950s and domestic flax output dwindled once the State had reallocated its subsidies to oil plants grown to meet the needs of the margarine industry. A decision to close down the oil press was taken in 1960. When Oy Schildt & Hallberg Ab celebrated its centenary in 1962, however, boiled linseed oil (varnish) still remained the largest single item in the company's product range.

Plant premises were renovated and expanded, more modern machinery installed and production rationalized, but no measure was enough. The suburban construction boom in Finland was crying out for paint. The production capacity of Schildt & Hallberg alone was simply unable to meet the sharp rise in demand

In 1967, the company acquired the Suomen Väriteollisuus Oy production units in Hanko. This added marine coatings to the product range, which further boosted the marketing of industrial coatings. The Korso plant of Suomen Väri- ja Vernissatehdas Oy came into the hands of Schildt & Hallberg in 1970. Despite acquisitions, it was obvious that only a vast new facility would secure the company's future.

Work on plans for a modern production facility to manufacture paints and other finishing materials started in the early 1970s. It was a large investment and the owner families did not wish to commit themselves. In 1972, what was then Rikkihappo Oy, now better known as Kemira, took over Oy Schildt & Hallberg Ab. In the spring of 2010 Tikkurila separated itself from Kemira and was listed on the Helsinki Stock Exchange.

Domestic demand was strong but the export market beckoned as well. The company's first international subsidiary, Fennia Färg AB, was established in Stockholm jointly with a competitor, the then Teknos-Maalit Oy. Tikkurila took over the sales company in 1976, and Tikkurila AB, which for a long time operated under the name Dickursby Färg, has achieved a strong name in Sweden as a supplier of industrial coatings.

The Monicolor tinting system launched in 1970 revolutionized both paint-making and distribution to a degree that few could have envisaged at the time. Paints were no longer produced in ready-made colors or tinted at the factory; instead the desired shade could be mixed in shops while the customer waited. There were 360 colors available – it seemed unbelievable.

When Schildt & Hallberg changed hands the location of the new production facility being planned was no longer merely a company matter. Decentralization was the prevalent trend at the time, and efforts were made to relocate government agencies and state-owned companies outside the Helsinki metropolitan area. Politics decreed that the new paint factory should be located in Iisalmi, a country town in Central Finland.

The project took wing when a consensus on location – Tikkurila, Vantaa – was finally reached. In 1975, the Monicolor plant and central warehouse became a reality: the world's most advanced automated paint factory that even today retains its standing as a leading-edge facility. The computer-controled, environmentally friendly production process, which is almost entirely closed and highly efficient in raw material use, was an unheard-of innovation at the time.

The company had earlier exhibited its progressiveness by hiring, in 1974, a full-time environmental manager, probably the second company in Finland to do so. Environmental issues originally related mainly to emissions from production, rather than those from products as is the case today. Fire prevention and industrial safety were focal areas of old.

The year 1975 also saw a change in the company's name, which became Tikkurilan Väritehtaat Oy – Dickursby Färgfabriker Ab. The Swedish language remained strong within the company though it started to lose significance after the company had changed hands and the proportion of Swedish-speakers among company employees steadily declined.

The importance of the Russian language, on the other hand, was on the rise. The Soviet Union, hectically preparing for the Moscow Olympics, consumed white Miranol paint as quickly as it could be manufactured. After the Olympics, sales of car enamels began – at first line paints for automobile plants and then touch-up paints for private use as well.

The year 1979 saw an intensified emphasis on the marketing of industrial coatings. Construction of a new industrial coatings plant and warehouses started in 1982. The Temacolor plant came on stream and the Temacolor tinting system for industrial coatings was launched in 1983. Tikkurila was the first company capable of standardizing both base paints and tinting colorants in a way that enabled the desired colours in paint to be achieved using tinting equipment at point-of-sale, without need for any corrections. Moreover, the same colorants could be used for tinting various types of industrial coatings.

Once the Novacolor plant was completed in 1988, the legendary No. 1 factory was consigned to the history books. Product development was another area of keen attention. The reasons for this could be found in increasingly international operations, tougher competition and more stringent regulations concerning industrial safety and the environment. A modern research and development center was built south of the River Keravanjoki: – its first phase was completed in 1984, the second in 1988.

With its acquisition in 1984 of the fourth-largest British paint manufacturer, Tikkurila entered the international market in a single leap. Donald Macpherson Group Plc had operations in eight countries, including Southeast Asia and the Caribbean. The Tikkurila Group now had a workforce of over 3,500. In 1986, the company adopted yet another name, more convenient for international business: Tikkurila Oy.

Trolley buses decorated with Tikkurila advertisements were a familiar sight in Moscow and St. Petersburg in the 1990s.

Tikkurila had been exporting paints and coatings to the former Soviet Union since the 1970s. At the time of the collapse of the Soviet Union in 1991, eastern trade was still responsible for a major share of the company's exports. The effects, however, were not overly drastic. A whole new customer segment was born in Russia: – consumers – and Tikkurila started serving their needs instead of those of industrial customers who had disappeared practically overnight. Paint demand remained strong in the domestic renovations market while the Baltic States and Eastern Europe presented a world of new opportunities.

Eastern expansion continued when Tikkurila established a joint venture with a chemical company in Estonia (still part of the Soviet Union) in 1989; paint production started in Tallinn (Estonia) in 1992. The following year paint production also started in Riga (Latvia), but later transferred to Tallinn and Vantaa (Finland). A sales company was established in Vilnius (Lithuania) in 1995.

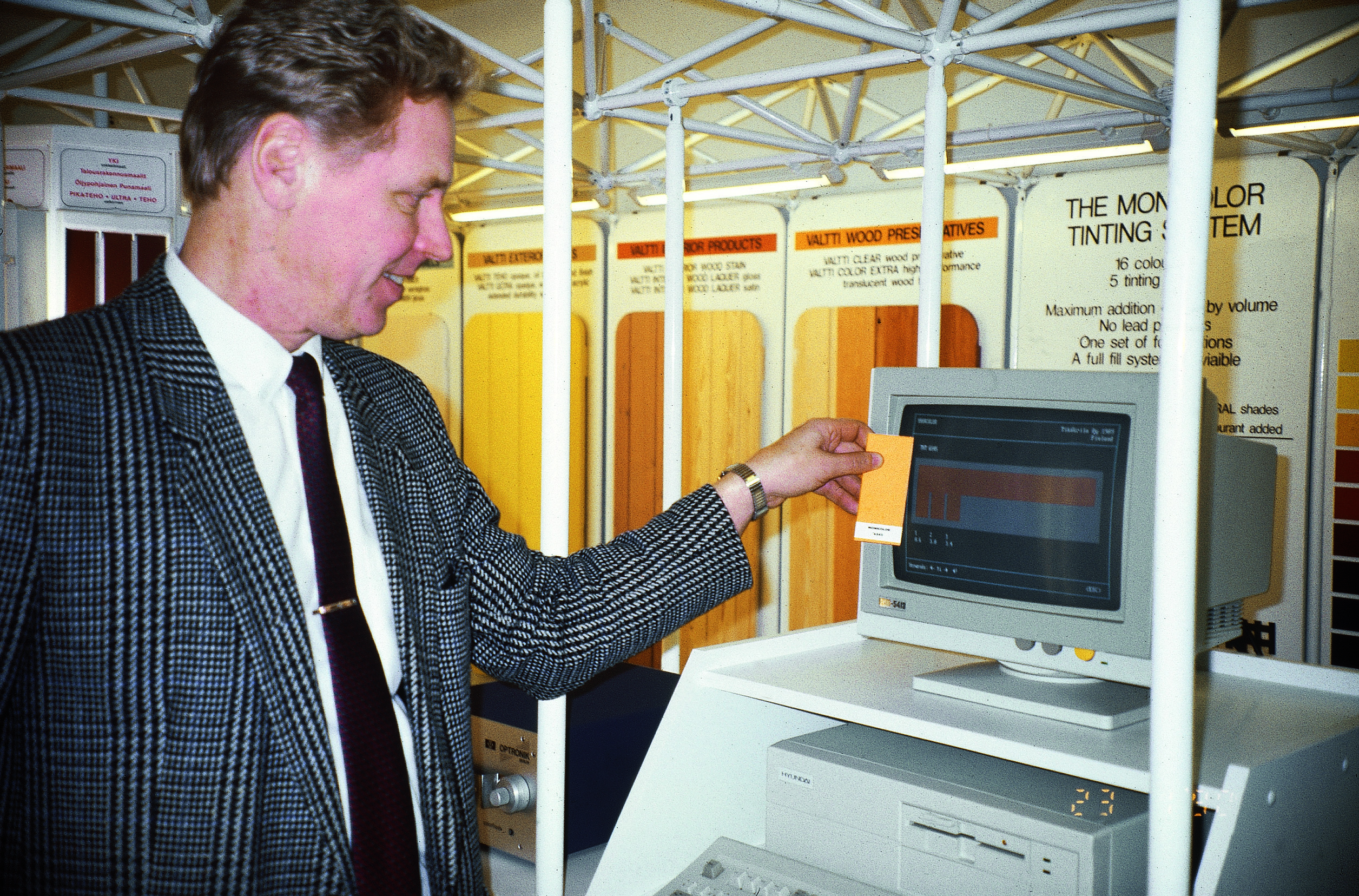

A great deal of investment had been poured into tinting since the 1970s and now the business was starting to show a profit in the international market as well. The 1982 Monicolor Futura tinting system had 600 colours; the Monicolor Nova introduced in 1992 boasted a whopping 2,024. The year 1990 also saw the introduction of the Värimittari color-matching equipment (spectrophotometer) that allowed a formula for any shade to be calculated in a matter of minutes.

In 1990 a Tikkurila sales office for marketing tinting systems instead of paints was established at Dordrecht, in the Netherlands. Timo Koski demonstrates the revolutionary color-matching equipment that calculates the tinting formula on the basis of a color sample.

Tikkurila survived the recession of the early 1990s largely unscathed. Tinting technology had already conquered Europe and was now embarking on other parts of the world. Acquisitions and new building resulted in Tikkurila having tinting-related component manufacture or assembly on all continents by the end of the decade.

In 1997 Tikkurila acquired its importer in Hungary and turned it into a sales company, currently known as Tikkurila Kft. Tikkurila Industrial Coatings had started operations in Hungary a couple of years earlier, and in 2005 these two companies were merged. In 1998 a joint venture in Szczecin, Poland saw daylight producing both decorative paints and industrial coatings, but was later merged with Tikkurila’s other operations in Poland. Tinting systems which had a wide choice of colors helped to gain ground in these new markets.

Trouble began when Tikkurila's competitors made up the majority of its tinting customers. In early 1997 the business was divided into various companies. Tikkurila CPS Oy was established to handle the tinting business, while Tikkurila Paints Oy focused on decorative paints and Tikkurila Coatings Oy on industrial coatings. Tikkurila Services Oy, as its name suggests, supplied services to all of the Group companies, their parent company being Tikkurila Oy.

In the same year, Tikkurila CPS acquired the Taotek Group, which had tinting equipment business in four countries. Tikkurila in 1990 had already acquired the tinting colorant business of Lohja-Winter, with production facilities in three countries, while down the years, Tikkurila had also established companies of its own on various continents. This is how Tikkurila CPS became the leading global supplier of tinting systems, with all the components needed for tinting in its range.

In October 2000 Tikkurila CPS was sold to Industri Kapital, a Swedish capital investment company, and Tikkurila went back to its roots of developing, manufacturing and marketing paint. Europe and Asia now became the main marketing areas. The company strengthened its position in Europe by acquiring Alcro-Beckers AB, the decorative paints business of the Swedish AB Wilhelm Becker, at the beginning of 2001. The deal included production facilities in Sweden, Poland, Germany and Finland as well as sales companies in Denmark and Norway.

Monicolor Symphony, a new tinting system, was launched in 1997. The number of base paints fell from five to two and even more environmentally compliant tinting colorants were introduced. The end of 2002 saw the launch of a new color system, Tikkurila Symphony, and a selection of new shop display equipment.

Temaspeed logoIndustrial needs were met with the Temaspeed system that contains all the most common Finnish and international color cards. The service concept, launched in 1998 and renewed in 2005, now has some 300 distributors in approximately 30 countries.

Tikkurila's reputation was based on more than just tinting. In 1994 it became the first paint plant in the world to receive environmental management certification. Today most Tikkurila facilities either already have in place or are working on environmental management systems. In 1997 Tikkurila’s Eko-Joker paint received the EU’s environmental label – the first product in Finland to do so.

In the 1990s Eastern European markets were in a state of flux. The first Western-style paint factory in Russia was opened by Tikkurila in St Petersburg in 1995, and another in Moscow in 2000. In the same year, a sales company and a warehouse were set up in Novosibirsk, the largest city of Siberia. Currently, Tikkurila enjoys a strong position in Poland, where exports began in the 1980s, and has also expanded to other Eastern European countries. Tinting expertise has proved a definite advantage in all markets.

In 2002 Tikkurila completed a major reorganization in Poland. For the decorative paints business, i.e. Alcro-Beckers and Tikkurila Paints, a new company was established, known today as Tikkurila Polska S.A. All of the paint production and R&D now takes place at Debica in southern Poland, and the administration is also handled from there. Sales and marketing are the responsibility of the Warsaw office, and the central warehouse and logistics center are located at Lodz.

Tikkurila Coatings continues its operations in Poland under its own name, although some operations are being carried out at Tikkurila Polska’s premises. The sales office for industrial coatings still remains in Szczecin in northern Poland, but production and the warehouse have moved to Debica.

Akzo Nobel Coatings' general industrial finishes business in the Nordic countries and Poland was acquired by Tikkurila in 2002. The next year saw the same happening in Hungary.

In the UK, Tikkurila Coatings Ltd moved in 2003 to a single site operation in West Bromwich, near Birmingham. Two years later the company was divested. Later in 2005, Tikkurila's coil coating business was sold.

A new training center – "Paletti" – was completed in Vantaa (Finland) in 2003. The center is a natural continuation of the company's long-standing training-course activities and, on the other hand, a response to the wishes of both customers and employees. Tikkurila's export operations were also badly in need of training facilities. Currently, most of Tikkurila’s operation countries have similar training centers.

From the beginning of 2004 Tikkurila Services Oy (a service provider within the Tikkurila Group) was merged with the parent company Tikkurila Oy. In 2008 Tikkurila Paints Oy and Tikkurila Coatings also merged with Tikkurila Oy.

In late 2004 Tikkurila took another step eastwards by acquiring a majority stake in a paint producer in Kyiv, Ukraine, and acquired the remaining stake two years later. Exports of paints and coatings have been made to Ukraine since the beginning of the 1980s.

In 2004 Tikkurila started to simplify its Group structure by combining its industrial coatings companies and decorative paints companies in the Baltic States and Hungary.

Russian market leader 2006

In February Tikkurila acquired the Russian paint company OOO KRASKI TEKS, at the same time achieving leadership in the growing decorative paints market in Russia. Tikkurila now had four decorative paint plants in the country, along with several regional warehouses and an extensive distribution network.

In July Tikkurila acquired the remaining stake in the paint producer Kolorit Paints Kyiv, Ukraine, and changed the company name to TOV Tikkurila.

In September Tikkurila went deeper into the East. The sales company TOO Tikkurila was established in Almaty, Kazakhstan for marketing decorative paints in the rapidly growing markets of Central Asia.

At the same time, an importer, later renamed Tikkurila s.r.o., was acquired in Prague, the Czech Republic.

A step into Asia 2007

Gamma logoIn April Tikkurila acquired a 70% share in two St. Petersburg-based paint companies, and the remaining 30% stake two years later. OOO Gamma Industrial Coatings is among the leading producers of metal industry coatings in the country. OOO Tikkurila Powder Coatings produces and markets powder coatings under its own OHTEK brand.

In May Tikkurila took the final step in entering the Asian market by establishing a sales company in Beijing. At the same time Tikkurila acquired the importer CEIEC-Feelings. The following year a sales office was established in Shanghai, mainly for the marketing of Tikkurila's industrial coatings.

In August Alcro-Beckers sold its 50% stake in the Swedish filler-producer Scanspac to Gyproc AB. Alcro-Beckers can now focus its efforts purely on paint manufacturing.

New production plant in Sweden 2008

In January the subsidiaries Tikkurila Paints Oy and Tikkurila Coatings Oy merged into their parent company Tikkurila Oy. This brought an end to the division into five different companies dating back to 1997. Tikkurila CPS Oy was sold in 2000 and Tikkurila Services Oy merged into its parent in 2004.

After more than 100 years of operating in Lövholmen (Stockholm) – Alcro-Beckers’ paint production was transferred in February 2008 to a new plant, fully integrated with the existing logistics center, in Nykvarn, some 40 km from Stockholm. A fully automated facility will support the company’s target of selling only water-borne products. A month later, Alcro-Beckers’ head quarters and Tikkurila Coatings AB moved to Hammarby Sjöstad in Stockholm.

In March Tikkurila Oy received the Brand Builder of the Year award from the Finnish Association of Advertisers. Special attention was given in the selection to the fact that Tikkurila has created added value in its marketing communications in the form of services to consumers, and consistently adhered to its chosen brand world.

In May, Tikkurila established a trading company in Bucharest, Romania, jointly with the Slovenian JUB.. Later Tikkurila acquired the remaining 50% stake in the company.

In August, the sales company IP Tikkurila was established in Minsk, Belarus, with responsibility for both decorative paints and industrial coatings.

In December 2008, Tikkurila acquired a sales company in Slovakia, later named Tikkurila Slovakia s.r.o.

Tikkurila continued its Group structure simplification process by merging its three decorative paints companies in Russia at the end of December. The companies now operate under the common name of OOO Tikkurila.

More input into Russia 2009

In February a new logistics and service center in Mytishchi near Moscow was opened to take on the challenges offered by the strong growth and increasing demand in the Russian paint market. The center also houses facilities for extensive customer training, which is an essential part of Tikkurila's marketing. All Tikkurila operations in Moscow are now located at the same site.

In May Tikkurila acquired the remaining stake in two St Petersburg-based paint companies. OOO Gamma Industrial Coatings is a producer of metal industry coatings and OOO Tikkurila Powder Coatings is a producer of powder coatings.

Since June all of Tikkurila’s Baltic companies formerly called Tikkurila-Vivacolor are known under the name of Tikkurila. The change is part of the Tikkurila Group's structure simplification process started in 2004.

In the same month the Swedish subsidiary Alcro-Beckers AB became the first company to receive the Nordic Ecolabel – known as the “Swan" – for its exterior paints. Two years later, five new Nordic Ecolabels were granted for Alcro and Beckers interior and exterior paints.

In August Tikkurila acquired the Slovenian company JUB’s stake in the Romanian joint venture and owns 100% of the company, now renamed Tikkurila SRL.

In September, Tikkurila launched its new Avatint tinting system based on the latest innovations in colorant and pigment technology; the system also observes the more stringent regulations related to volatile organic emissions (VOCs) from paints and coatings. The Feel the Colour selection and Visio shop-in-shop concept were launched simultaneously. The novelties have been introduced step by step in Tikkurila’s various countries of operation.

ObukhovoIn December modern production lines for water-borne paints opened at Obukhovo, St. Petersburg. This compact, semi-automated facility, based on Western technology, allows very flexible production.

In the beginning of 2010 a new “Corporate Responsibility” program was adopted as a replacement for the Group-wide program dating back to 2001. The progress made in achieving targets is reported yearly using the international GRI guidelines.

Tikkurila Oy changed its company name to Tikkurila Oyj from February 17, 2010. Tikkurila was listed on NASDAQ OMX Helsinki Oy on March 26, 2010, when trading began with the Tikkurila share. The former sole owner (Kemira Oyj) was replaced by more than 30,000 shareholders. At the end of 2011 shareholders numbered around 23,000.

In April Tikkurila's Visio shop-in-shop store concept was awarded the so-called "Hopeahuippu" (silver award) for service design at the Grafia Association's "Best of the Year" event, Finland’s most important marketing communications and design competition.

In October, Tikkurila launched the Tikkurila ProHouse concept for wooden houses at the FinnBuild 2010 Fair in Helsinki. The idea of the ProHouse surface treatment is to produce ready-to-use wooden materials for manufacturers of prefab houses, building companies and consumers.

Tikkurila participated in the Shanghai World Expo as a partner of Finpro’s Finland at Expo 2010 project. Finland's "Giant's Kettle" pavilion received a Golden Statue for the best Pavilion Design in its category. Tikkurila had supplied paints and lacquers for the pavilion's steel frame, and all of the interiors, as well as the entrance and the courtyard exterior walls.

In January Tikkurila sold its powder coatings business in Russia.

In addition to white, this colorful work of art was painted using 68 tailor-made shades of Harmony paint.

Co-operation between Tikkurila and the Museum of Contemporary Art Kiasma in Helsinki acquired new vibrancy through the ARS 11 exhibition running from mid-April to the the end of November. The wall painting "Time Curve" created by the world-renowned artist Odili Donald Odita covered approx. 100 square meters of the Panorama space of Kiasma.

In July Tikkurila acquired the business operations of the Serbian paint company Zorka Color d.o.o. The company has operations in Serbia and Macedonia.

Tikkurilan ammattilaispalvelutIn October, the Profe – Tikkurila Professional Services concept was launched at the Colour and Surface 11 fair in Helsinki. "Profe" is a service concept for professional customers, which allows Tikkurila to provide more extensive and targeted services for various operators in the trade. The services were taken into use immediately in Finland. In Tikkurila's other countries of operation, the aim is to adopt same concept later.

In November Tikkurila Oy received the Nordic Ecolabel known as the “Swan” for its two interior paints. The Swedish subsidiary Alcro-Beckers AB already has several “Swans” for its products, and today the Tikkurila Group has the highest number of eco-labeled decorative paints in the Nordic countries.

In October, Tikkurila’s Board of Directors decided upon a revised Group strategy. The target is to be the leading paint-related architectural solutions provider for consumers and professional customers in the company’s geographic area. Growth is targeted especially organically by utilizing strong brands, by developing distribution solutions and to the relevant extent by entering into service business. Efficiency will be enhanced in all operations.

After announcing its revised strategy, Tikkurila signed in November a letter of intent to sell its three sales companies in Hungary, Slovakia and the Czech Republic to a Czech company to be established by Tikkurila's local management.

In December, two retail stores – one in Stockholm and another in Uppsala – were sold to the then head of Tikkurila's SBU Scandinavia, and to other private persons.

In order to secure competitiveness in an uncertain and rapidly changing market environment, Tikkurila decided to start a group-wide program in November aiming at a more flexible organization and cost structure, as well as at streamlining all operations.

Tikkurila turned 150 years in 2012. The official anniversary is on August 14, but the anniversary was celebrated together with various stakeholders throughout the year. The anniversary year look and feel was tied together by the official emblem, the visual concept, and the "Colorful visions since 1862" slogan.

In 2012 Tikkurila was committed to promoting the well-being of people of all ages by participating in projects that enhance their environment with paints and colors. As part of the anniversary year Tikkurila introduced the “Sustainable Beauty” program for social responsibility, with the aim of further emphasizing Tikkurila's responsible approach in the markets and areas where the company operates.

In June 2021, Tikkurila Oyj was acquired by PPG Industries Inc., and the company was delisted from Nasdaq Helsinki on October 29, 2021.